Optimize the curing process of concrete products and increase efficiency

Best conditions for the best quality concrete blocks.

For more than 70 years, ROTHO provided solutions for the concrete block industry worldwide. We understand our clients‘ high pressure demands caused by the competition from a dynamic market and are aware of the constant technological development in order to further increase the effectiveness of plants.

We recognize the importance of a secure production environment. We are constantly enhancing the development of our ROTHO systems in order to increase production levels and prevent downtimes. Together we create perfect conditions for the best quality concrete blocks.

The most intelligent system for storing concrete products throughout the curing process.

- Quality-Rack-Design “Made in Germany” with a high durability

- Proven rack construction with experience from more than 2500 installations worldwide

- From standard construction kits to individual solutions all from one source

For a uniform curing climate and reduced curing times.

Concrete Curing System ProAir

- Highest circulation capacity for uniform temperature - and humidity distribution

- Long service life due to high quality design

- Reduction of condensation

Sustainable and energy saving - For ProAir recirculation systems

Additional sensors mounted on different rack levels measure the temperature inside the curing chamber. Delta-T- Control makes it possible to control the temperature difference by a frequency converter.

- Reduction of electricity costs up to 60%

- Reduced wear out on the fans

For consistently high quality results all year round and reduced curing times.

- More consistent colour results

- Less efflorescence

- Reduced edge breakage

- Cement cost savings

- Maintenance-friendly and energy efficient

Various system variants available, including with warm water heat exchangers for the use of sustainable heat sources (geothermal, solar thermal, etc.)

Optionally with active humidification

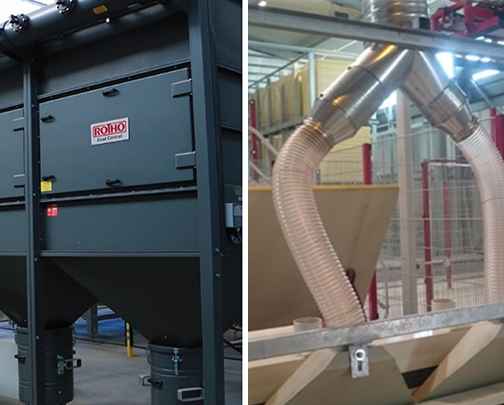

Sound insulation for concrete block machines

- Reduction of the noise level

- Comprehensive equipment program (Doors, windows, etc.)

- Individual planning and customization

Optionally with Control & Switchboard Rooms

The compact, robust filter unit with replaceable cartridge filters for cleaning the cabin air

- Electronic cleaning automatic

- Robust and durable filter system

- Maintenance-friendly and energy efficient

Process-integrated and highly stable storage systems for moulds and production boards.

Stackable pallets for concrete tiles and Pallets for concrete sleepers & large-format concrete parts

- Optimally statically designed for every application

- Highest manufacturing precision

- Stable design for robust operation

- Durable thanks to galvanised surfaces

Diverse options

For a wide variety of concrete blocks.

-

Concrete slabs -

Curbstones -

Hollow bricks -

Paving stones -

and many other concrete products

Downloads

Find out more about our solutions and the best possible conditions for your processes.

Impressions

Concrete goods made with ROTHO