We create the best conditions for your curing and drying process.

Excellence in concrete and tile technology.

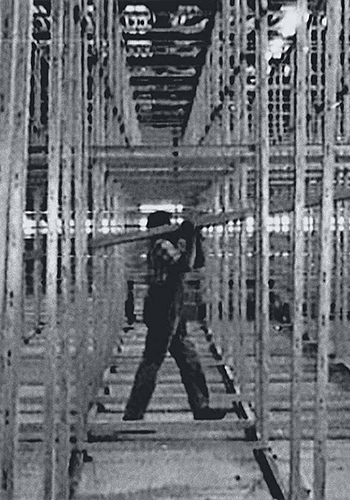

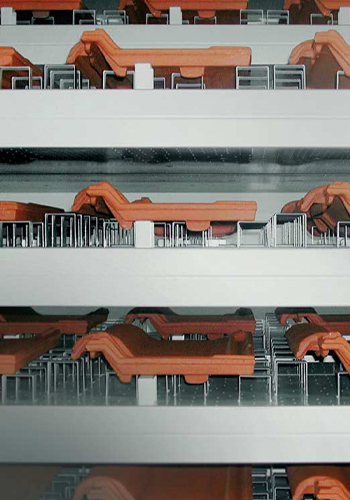

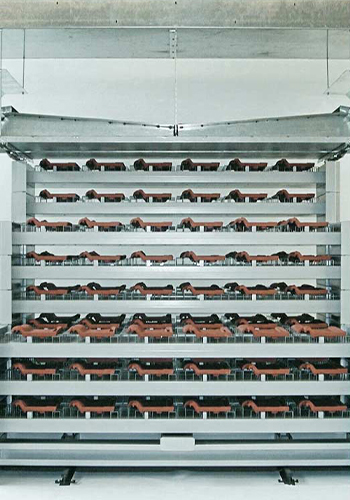

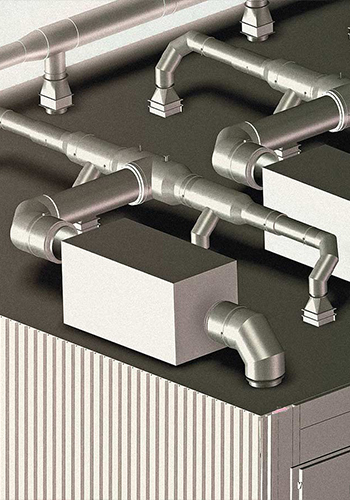

We have been providing solutions for the concrete and brick industry worldwide for over 70 years - constantly aware of the ongoing competitive pressure from our customers and their continuous efforts to increase plant efficiency. Our ROTHO systems are designed to increase production volumes and minimize plant downtime.

Production in our own factory in Germany guarantees a high standard of quality and great flexibility. Together we create ideal conditions for high-quality products.

The heart of ROTHO

With solid values and a look onto tomorrow

Experience

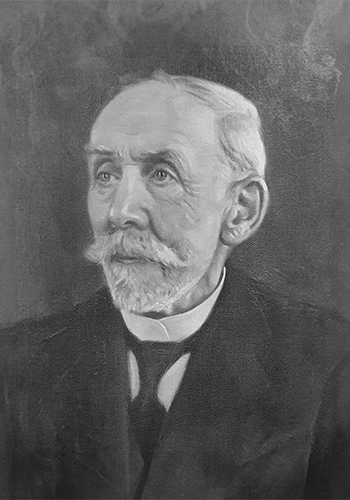

Guaranteeing quality since 1900 and an average length of service of 25 years: We develop the best systems for you!

Innovation

ROTHO already offers unique, intelligent systems that optimize and automate concrete and brick plants using digital tools.

Tradition

Because tradition endures: Our customers know that with ROTHO, spare parts and services will continue to be available in the future.

Sympathie

We maintain close and long-term cooperation with our customers. This enables us to develop the best solutions and we are delighted with their success.

Tradition and innovation.

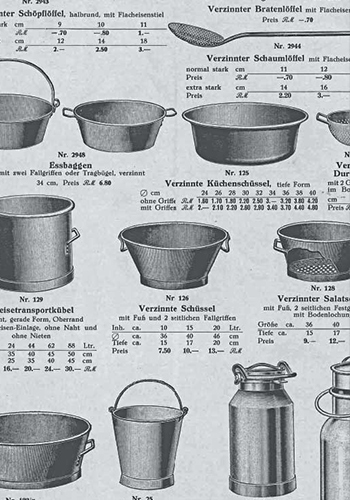

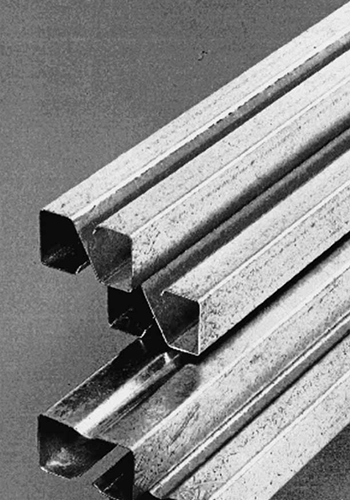

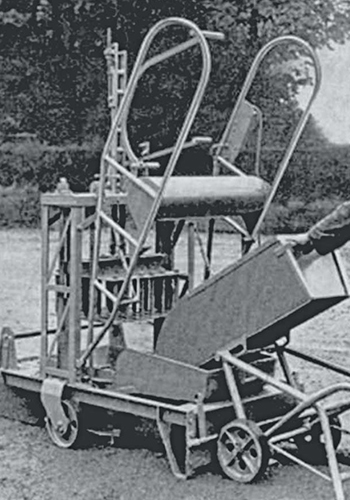

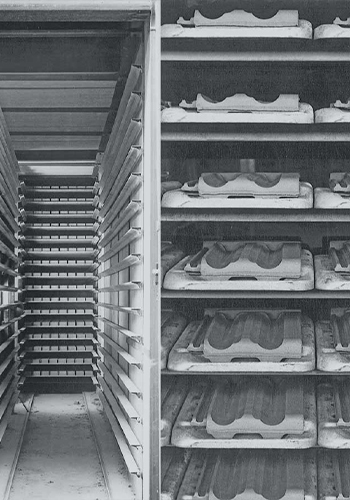

The history of our company spans four generations and is linked to the Siegerland metal industry. Founded by Robert Thomas in 1897, the company began with tool and fixture construction for the local industry. ROTHO later expanded its range to include sheet metal products for storage and transportation systems. In the 1950s, the company revolutionized the brick drying market with metal drying racks, which replaced wood and improved safety and quality in brickworks and concrete plants.