Optimize pouch sterilization and increase efficiency

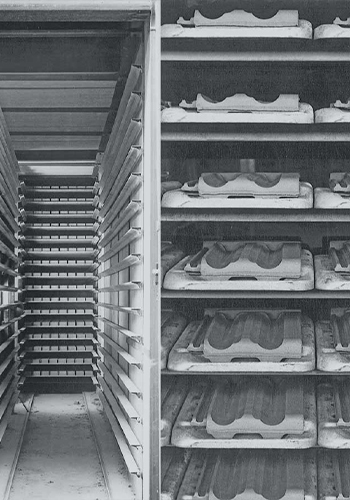

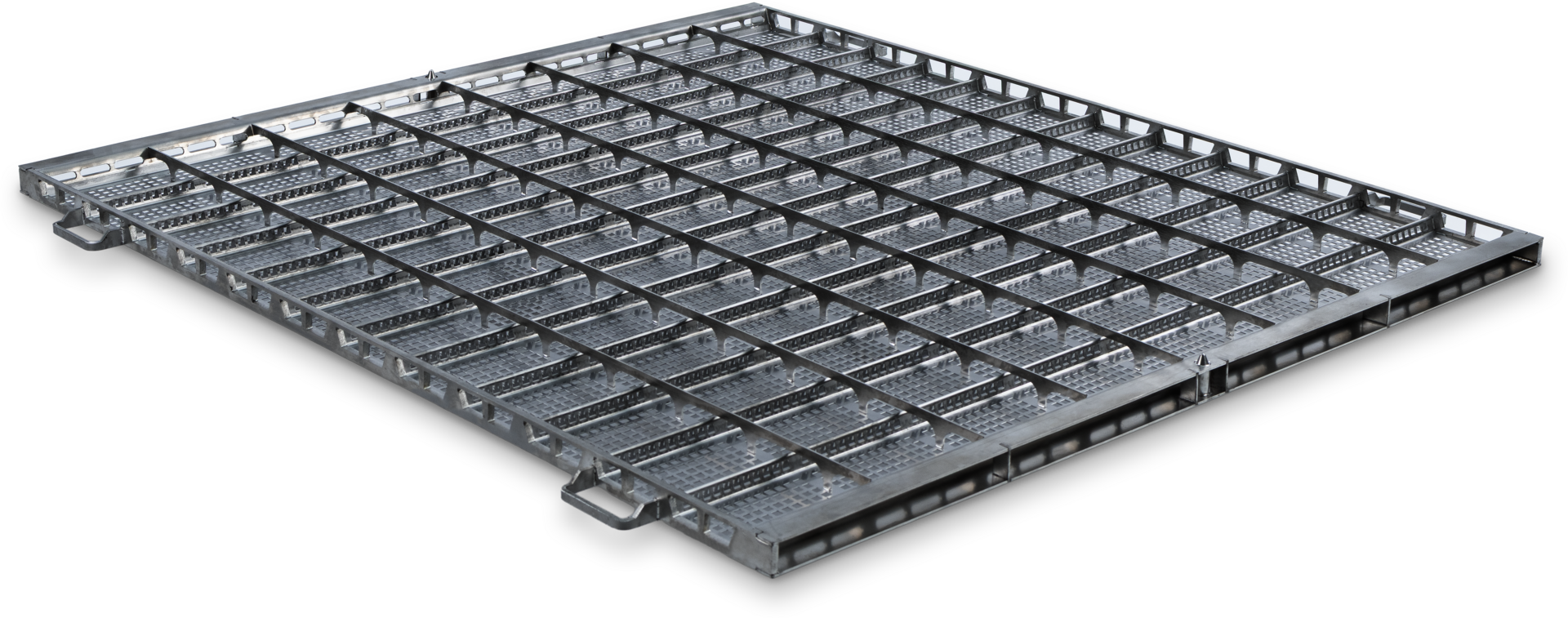

Sterilization trays from ROTHO

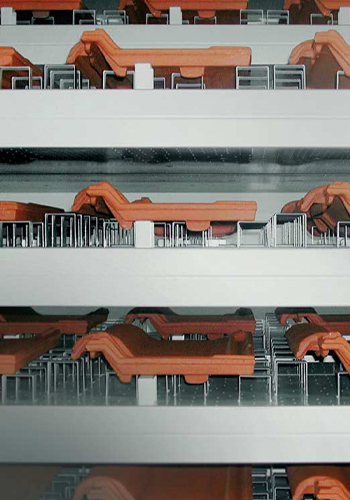

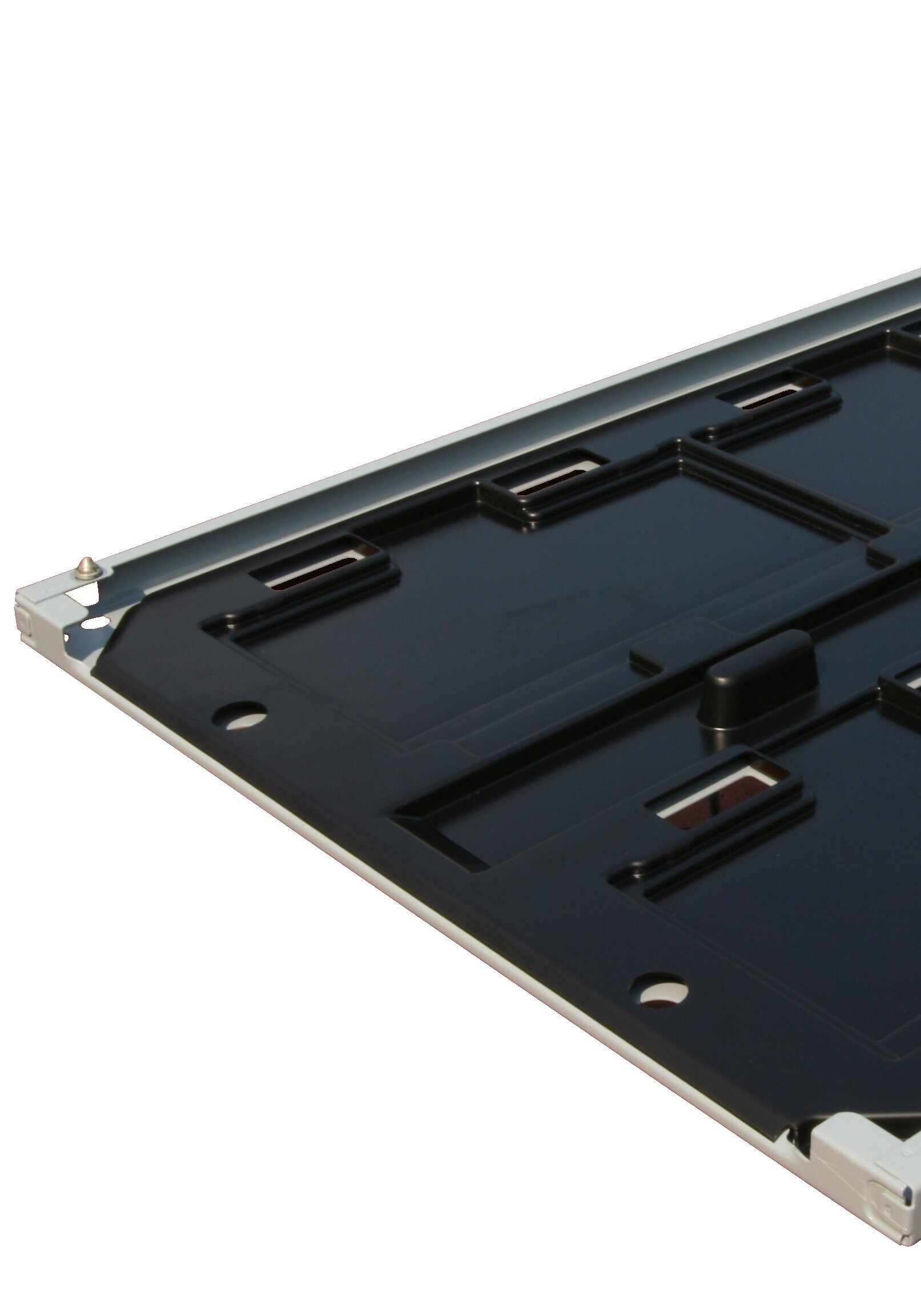

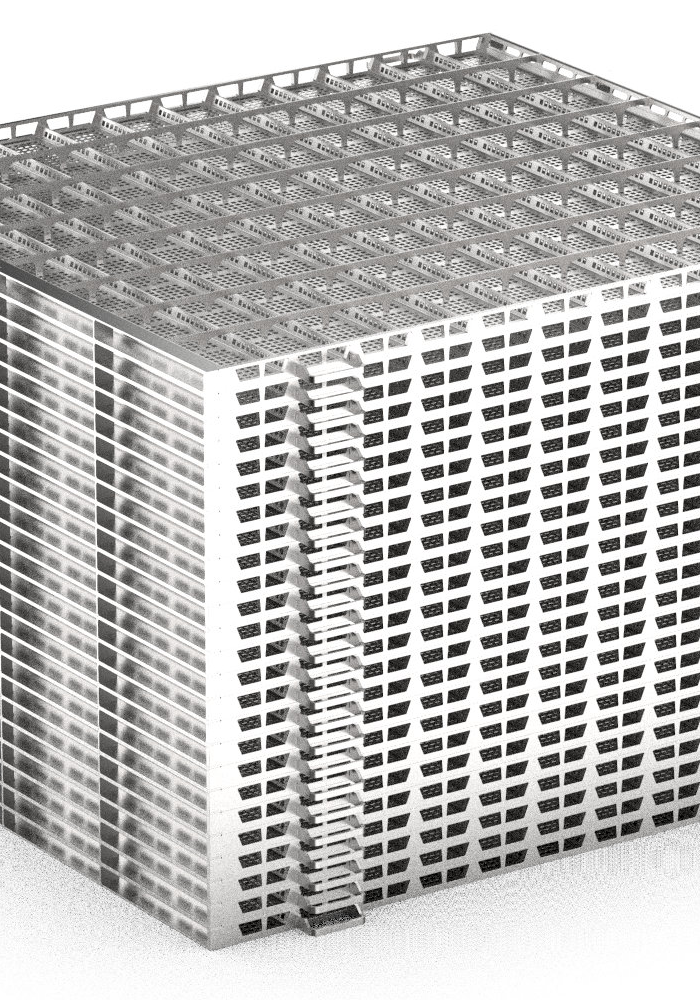

Optimize your production process with ROTHO sterilization trays

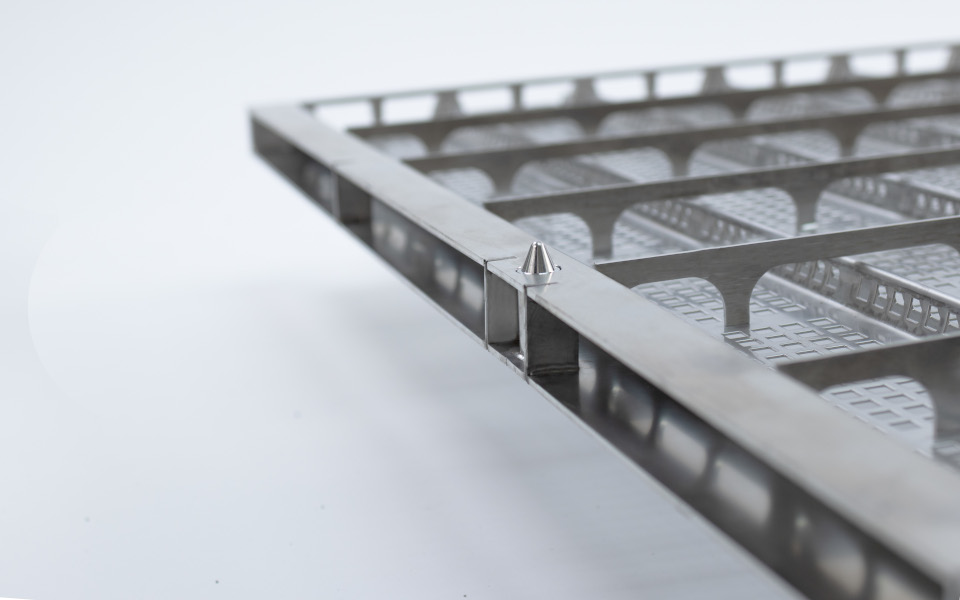

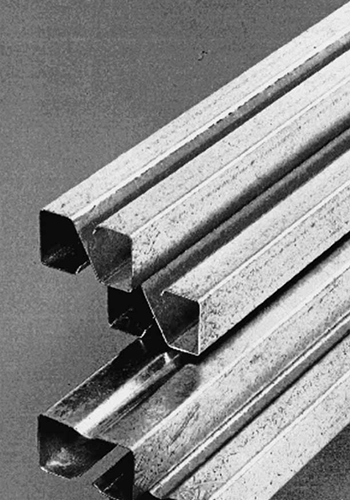

Reduce cycle times, improve handling, and increase the efficiency of your sterilization system with custom-designed stainless steel carriers from ROTHO.

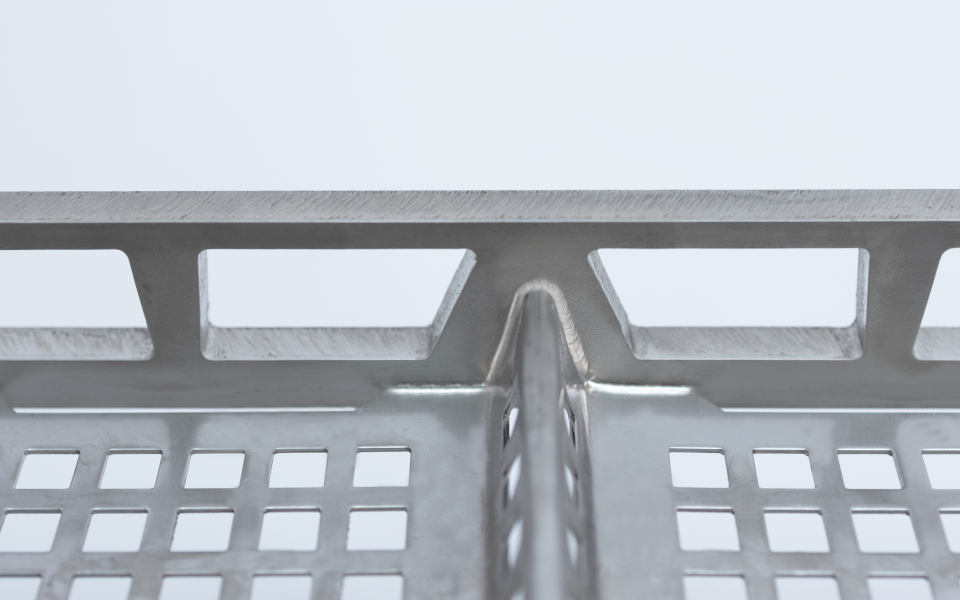

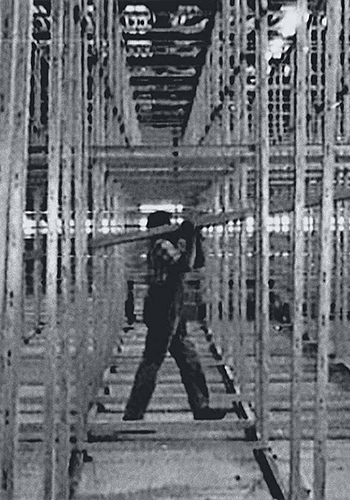

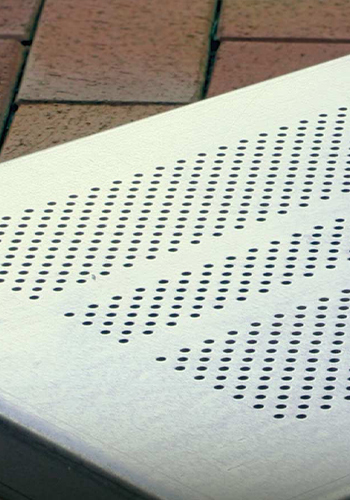

Together with our customers, we analyze existing processes and develop sterilization carriers that are precisely tailored to the respective requirements. Thanks to our experienced development team, optimization potential can be realized in a targeted manner—for example, reduced stack height or improved steam and water circulation. In many cases, this results in shorter sterilization cycles and higher plant utilization.

Adjustments to the geometry and materials used also result in solutions that absorb less heat energy, making the sterilization process more energy-efficient. Our trays are made of high-quality stainless steel and meet the highest standards of hygiene, durability, and corrosion resistance.

With over 100 years of experience in metalworking, ROTHO stands for quality, precision, and technical advancement—for efficient sterilization processes in the modern food industry.

Our Highlights

Your contact person

Florian Renninghoff

Sales Manager - Sterilization Trays

Tel.: +49 2735 788 543

E-Mail: florian.renninghoff@rotho.de

Reliability, Innovation and Tradition.

The history of our company spans four generations and is linked to the Siegerland metal industry. Founded by Robert Thomas in 1897, the company began with tool and fixture construction for the local industry. ROTHO later expanded its range to include sheet metal products for storage and transportation systems. In the 1950s, the company revolutionized the brick drying market with metal drying racks, which replaced wood and improved safety and quality in brickworks and concrete plants. Later, the product portfolio was expanded to include trays and special pallets for various applications and industries.