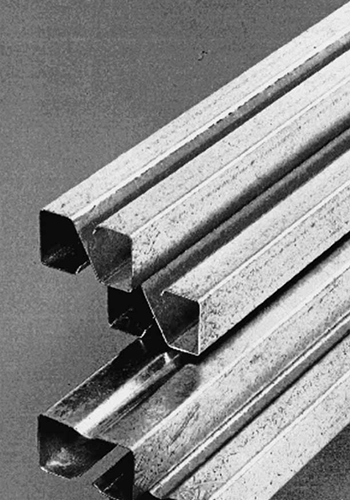

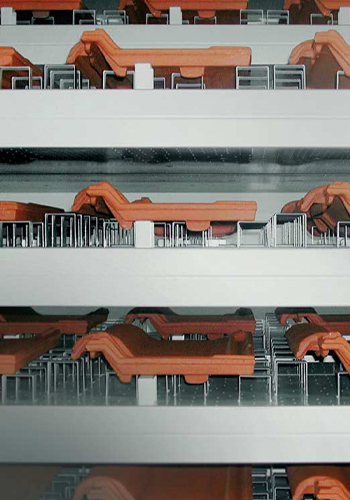

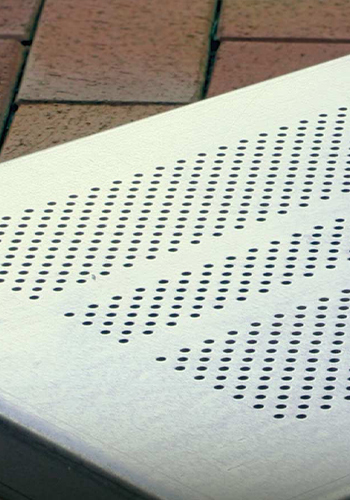

Optimize the curing process of concrete products and increase efficiency

ROTHO. A brand of the Robert Thomas Group

Find your place as an innovation driver via the Robert Thomas career portal.

We offer you space for new ideas! At our factory in Neunkirchen, we manufacture products with the highest standards of quality, durability and practicality. Characterized by a strong sense of tradition, we are firmly rooted in the Siegerland region. We employ around 280 people who are highly motivated and qualified. We have been training our own junior staff for 50 years. You can expect an open corporate culture with flat hierarchies and a collegial environment with a high level of professional expertise coupled with a trusting relationship with customers and colleagues.

Find your place as an innovation driver via the Robert Thomas career portal.

Tradition and innovation.

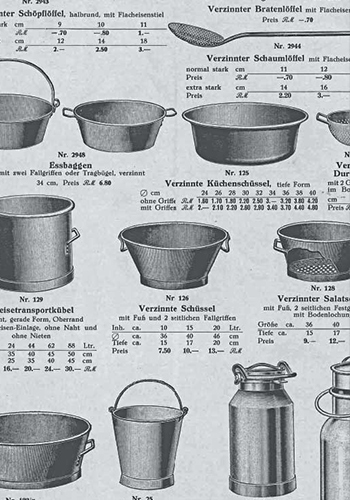

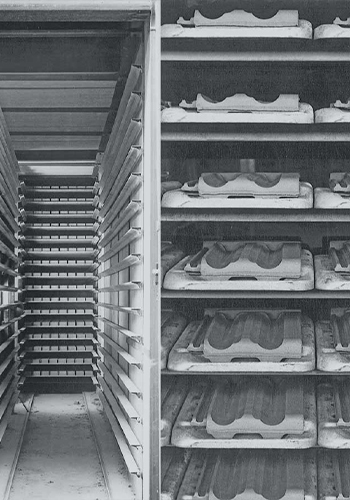

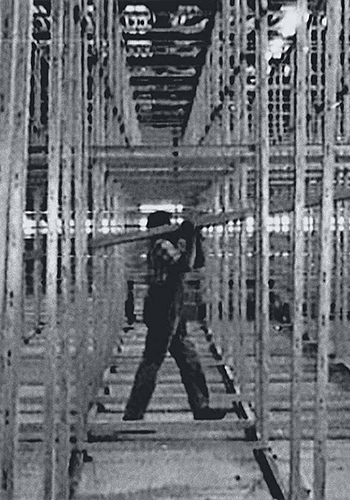

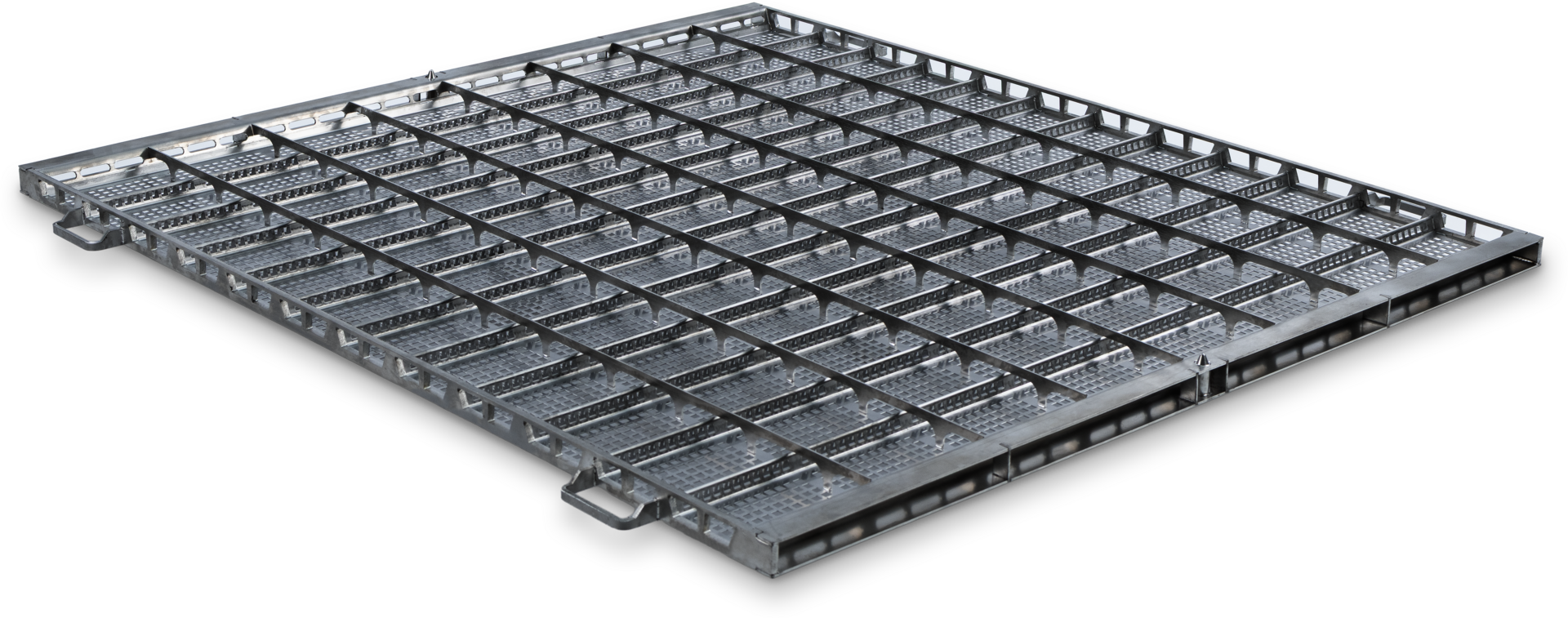

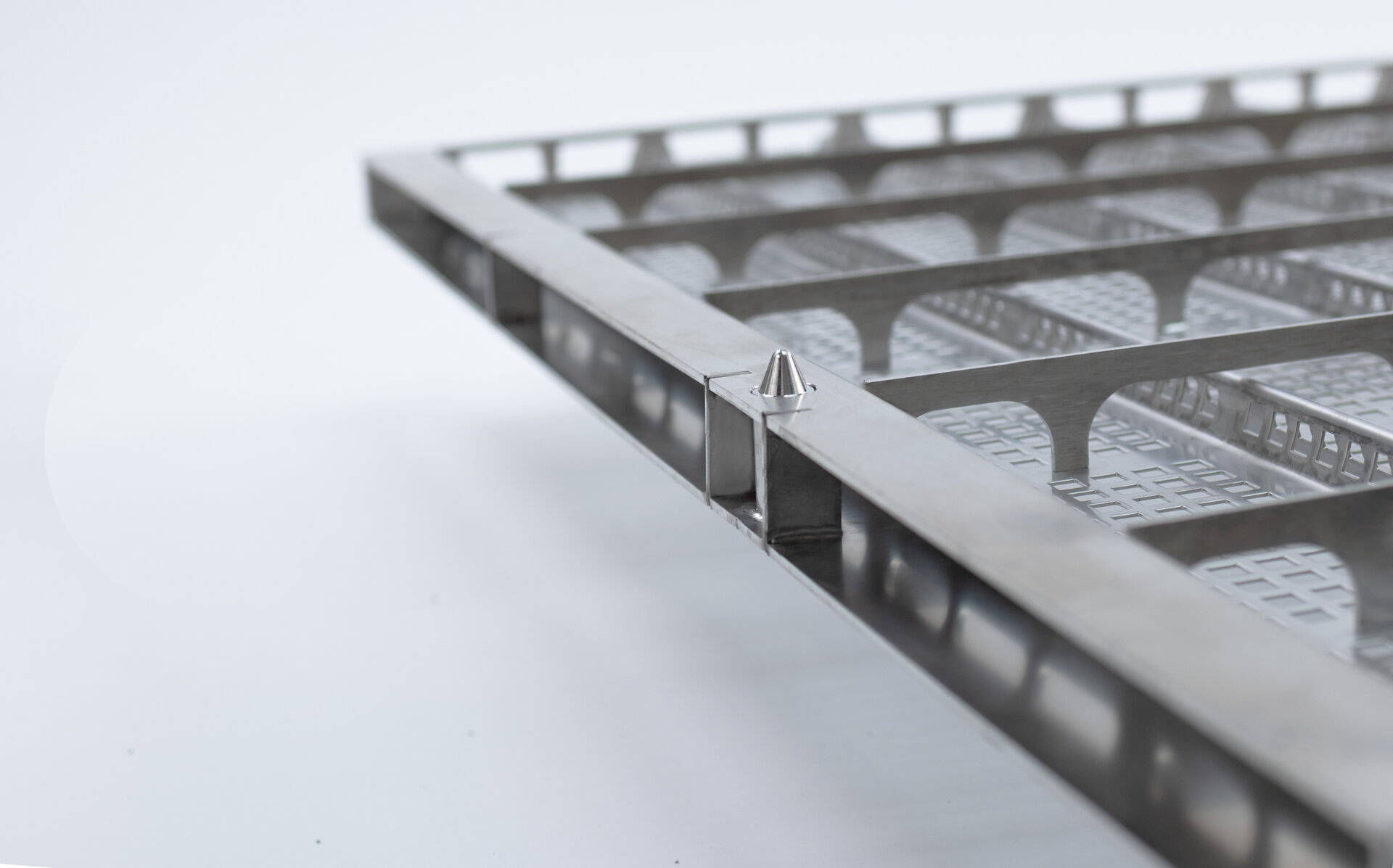

The history of our company spans four generations and is linked to the Siegerland metal industry. Founded by Robert Thomas in 1897, the company began with tool and fixture construction for the local industry. ROTHO later expanded its range to include sheet metal products for storage and transportation systems. In the 1950s, the company revolutionized the brick drying market with metal drying racks, which replaced wood and improved safety and quality in brickworks and concrete plants.

A strong team

Your contact person at ROTHO

Florian Renninghoff

Vertrieb Industrieanlagen / Sterilisationsträger

Tel.: +49 2735 788 543

E-Mail: florian.renninghoff@rotho.de